OpenLab is developed and managed by the Energy Modeling & Automation group of NORCE Energy, in collaboration with the University of Stavanger. We offer a world-leading simulation environment within drilling and well technology for education, research, and innovation.

Our Team

The OpenLab development team has been working together since 2015 and draws on expertise from the world-leading research community in automated drilling at NORCE, from lecturers at universities worldwide, and from renowned national IT expertise.

Our Mission

The mission of OpenLab drilling is to become a world-leading, independent, and easy-to-use infrastructure within drilling and well R&D. OpenLab is a one-of-a-kind infrastructure that accelerates research and increases the uptake and acceptance of new technology.

Our Product

OpenLab is the ground-breaking integration of the physical and virtual drilling and well operations, which is new and unique to the drilling world. For a more technical description of OpenLab, we refer to the publications.

Developed here at NORCE - Norwegian Research Center, the project is a combination of three systems:

- Web-based drilling simulator

- Drilling control room

- Integration with a full-scale on-site operational drilling rig

Web Client

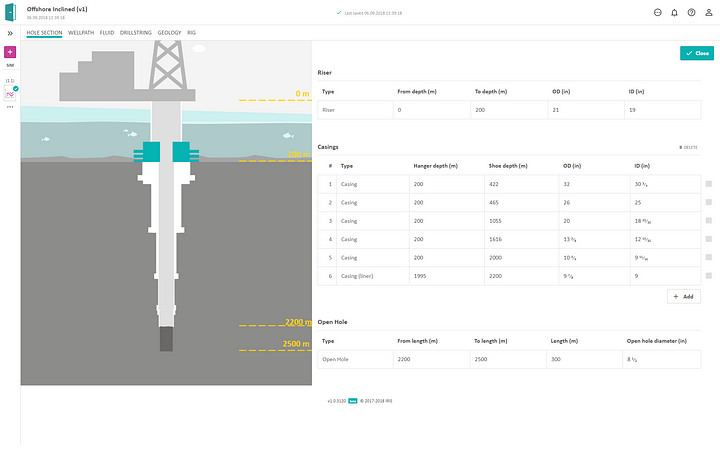

At the heart of OpenLab is the web-enabled drilling simulator. It takes one of the most tested and validated well models in the world, which has been developed for over 30 years at NORCE (former Rogaland Research and IRIS), and brings it to a user-friendly, web-based application.

"OpenLab Drilling is an ingenious, easy and an intuitive web application that neatly hides all the complex algorithms and technical details and presents a clean, user friendly interface to test and play with a large number of drilling and well scenarios.” -user

It can act as a standalone component within OpenLab, where it serves as an educational, developmental, and testing platform for students, lecturers, and researchers within the drilling community.

The application facilitates all levels of expertise from the absolute beginner to the knowledgeable industry user. The beginner user can choose from one of our numerous pre-made and optimized configurations, with no need to input or change anything, before running simulations.

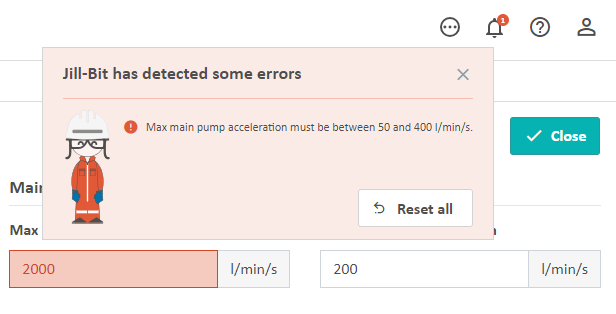

Our more experienced users can use our configuration editors to customize everything from the casing design, wellpath, drilling fluid properties, drillstring elements, formation properties, and special rig equipment. And if you make any mistakes, Jill-Bit will be there to help you along the way.

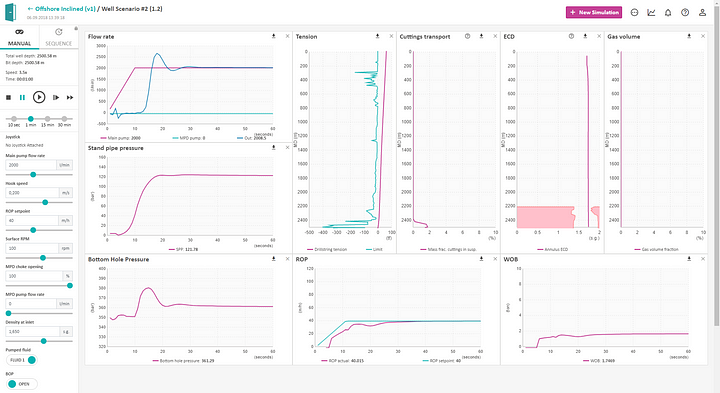

Simulations can be run interactively in real-time, single-step, or fast-forward mode, and even with a supported joystick. Alternatively, simulations can be run in sequence mode with pre-defined setpoints at times. These setpoints can either be imported as a CSV file or created using our sequence table editor.

While a simulation is running, select from over 30 time-based and depth-based results to display on the simulation page. Once you have found a layout that you like, you can save it as your default. Additionally, the simulator can also be run through our Matlab or Python packages, which allows testing of new software with feedback from artificial measurements from the simulator. These packages can be downloaded here.

Drilling Control Room

The drilling control room is a facility for research, innovation, and demonstration of new drilling software, control systems, and drilling concepts. Downhole simulations can be run with a large variety of scenarios with 3D visualization of the drill floor. Drilling control systems will be available with user-friendly access, also for non-vendor-specific software.

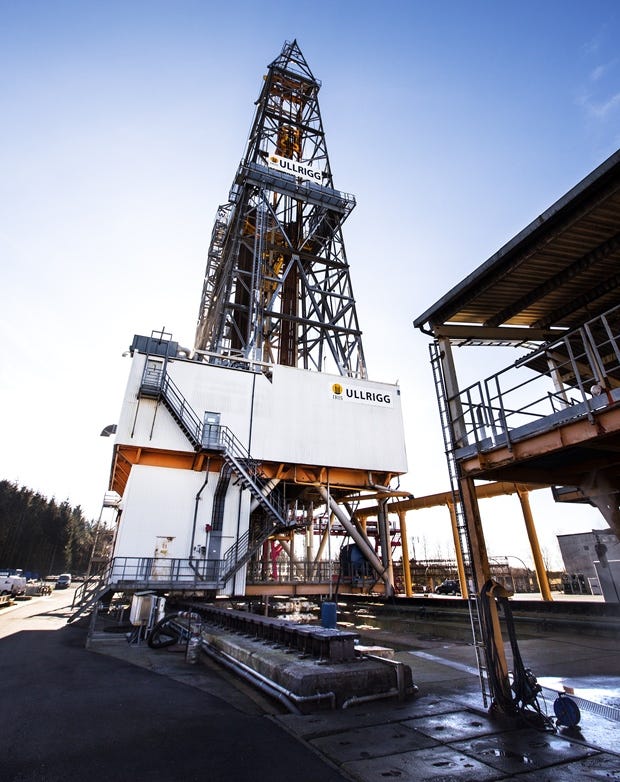

Ullrigg

The physical rig, Ullrigg, is the world's most advanced full-scale drilling test site in the world and includes an offshore-style drilling rig with access to seven wells. Measurements from surface and downhole sensors can be partially replaced by artificial measurements from virtual wells using the OpenLab simulator, and the drilling control system used on Ullrigg has a replica installed in OpenLab.

Who’s Using OpenLab

Get started using OpenLab today! Using a Google or Microsoft account, you can create a trial account at live.openlab.app and try the drilling simulator for free!